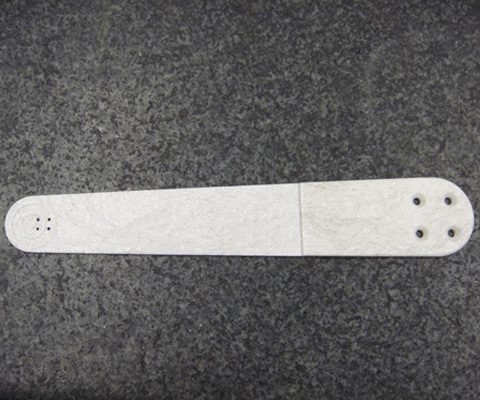

Mycalex Ceramic Vacuum Arm

This component is composed of 0.125″ thick machining-grade, Mykroy/Mycalex MM 500 glass-bonded mica composite sheets. Raw material was milled to dimensions of 6.065″ x 1.250″ x 0.110″, utilizing our advanced vertical machining centers, equipped with vacuum plates.

This added feature provides a uniform work-holding pressure, which allowed us to easily achieve the precision tolerances of ±.0005″ on perpendicularity and ±.002″ on parallelism. After deburring we applied a PTFE coating and hand polished the vacuum rings to a 16 RMS surface finish.

At each step of the process, we employed sophisticated metrology equipment, including CMMs and surface finish analyzers, to ensure specifications were met and critical dimensions maintained. Our ability to consistently hold tight tolerances while executing multiple processes, from highly automated milling to precision hand-polishing, ensured the integrity of this critical piece. To learn more about this project, or how our skills can improve your next project, contact us today.

Highlights of this Project

- Vacuum arm rotates chip wafer inside Track Equipment.

Primary:

- CNC Milling

Secondary:

- Deburring

- PTFECoat

- Tape

- Hand Polishing Vacuum Rings

- Vertical Mill with a vacuum plate.

- Length: 6.065″ – 7.255″

- Width: 1.250″

- Depth: 0.110″

- 0.0005″ Perpendicularity

- 0.002″ Parallelism

- Mykroy/Mycalex MM 500 Machining Grade Glass-Bonded Mica

- Composite Sheet

- Thickness: 0.125″

- 16 RMS Surface Finish

- Teflon Coated

- CMM, Vacuum Test

- Dimensional Inspection

- Visual Inspection

- Semiconductor

- 50 – 60 pcs/year

- 3-4 Weeks

- FOB Origin

- ISO 9001:2015

- Customer Specifications, 2D CAD Drawing

- Ceramic Vacuum Arm